DIY 2-Way Inflation and Deflation System – Step by Step Install and Overview

This is my take on a 2-way inflation and deflation system for all four tires mounted on the 5th Gen 4Runner.

There are DIY 4-way inflation and deflation systems out there as well as pre-built 4-way inflation and deflation kits available but I wanted to get one going myself.

I started with the ARB air compressor which has 1/4 NPT standard connection.

I choose 1/4 OD quick connect for all the parts I need. You can use a bigger diameter, but just make sure that you have 1/4 male NPT to connect to your ARB compressor.

Parts that you will need:

- Pneumatic Air Line 1/4″ Od Pneumatic Nylon Tube (x2 32.8ft): Check Price

- 1/4″ PT Male Thread 6mm Straight Pneumatic Push in Quick Fitting Connectors (1 pack): Check Price

- Plastic Push to Connect Fittings Kit, 1/4″ 6mm Od Quick Release Connectors (1 pack): Check Price

- 5-Way Air Manifold with 1/4″ Industrial 6-Ball Brass Couplers (4-way or any way; you can option less air-way): Check Price

- AstroAI 4 Pack Air Chuck, Heavy Duty Closed Flow Lock On Tire Chuck or you can use the Haltec H-5265 Standard Bore Lock-On Air Chuck: Check Price

- Haltec H-5265 (the best air chuck you can buy): Check Price

- Stainless Steel 304 Single Scale Liquid Filled Pressure Gauge with Brass Internals, 0-160 psi, 2-1/2″ Dial Display, +/-1.5% Accuracy, 1/4″ NPT Bottom Mount: Check Price

- Mini Ball Valve, Lever, 1/4″ NPT Male x NPT Female: Check Price

- Vixen Air Inflation Schrader Valve with Push to Connect (PTC) for 1/4″ OD Air Line: Check Price

- Note: this air inflation is the best, makes the installation process easy.

Tools that you will need:

- Zip ties

- Cutters

- Open and close wrench ratchet;

- 13mm

- 14mm

- 19mm

- Teflon tape

- Drill

- Drill bit 5/16

- Spray Bottled For Water + Soap

How the 2-Way Inflation and Deflation System Works

This project is simple, easy and it took me 30mins to install. Saves you storage and minimize those air hoses.

It also gives you more time to do anything else rather than bending down to air down and air up.

Step 1. Find a Location For Air Manifold, Tube & Valve

First, figure out where to put your air manifold, air tube, and air valve. I put mine on the front, behind the grill, that way I can see the gauge even the hood is closed.

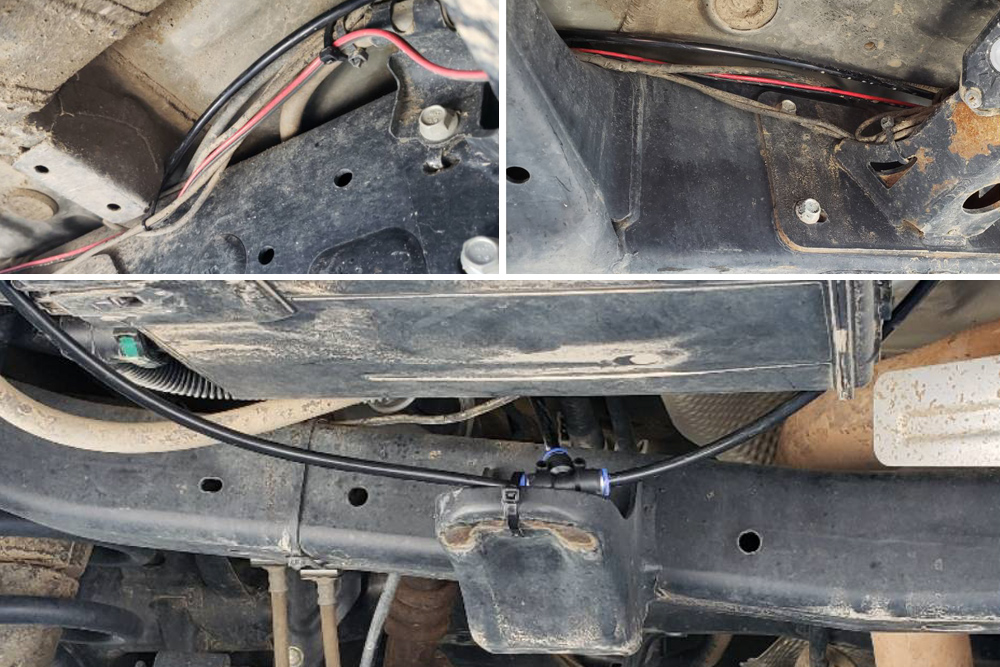

Next, place the tube onto the top left of the frame away from the exhaust. You do not want to burn that and have air leak later on.

Step 2. Cross Tubing Over Gas Tank

Cross the tube on the top of the gas tank and place it in the middle.

As you can see, I used a plastic push to connect fittings kit, 1/4″ 6mm OD quick-release connector and placed it in the middle of the lines. Measure the nylon tube from both rear tires and use the T-connect to split from left to right.

Look for a good location to put your air inflation. Drill 5/16 on the body and put the Vixen Air Inflation Schrader valve with push to connect (PTC) for 1/4″ OD Air Line.

Step 3. Secure Inflation Valve & Connect Pneumatic Air Line

Use the 13mm wrench ratchet and the open ratchet, secure the inflation valve then connect the pneumatic airline 1/4″ Od pneumatic nylon tube.

This will be the same steps for the front.

Step 4. Split Nylon Tube with T-connect & Add Valve Control

Next, you’ll need to split the nylon tube using T-connect and add valve control.

Wait, why do I need valve control?

Valve control is needed to control and calibrate the air from the front to rear. So, just in case, you’ll be able to make the front air up or down faster than the rear.

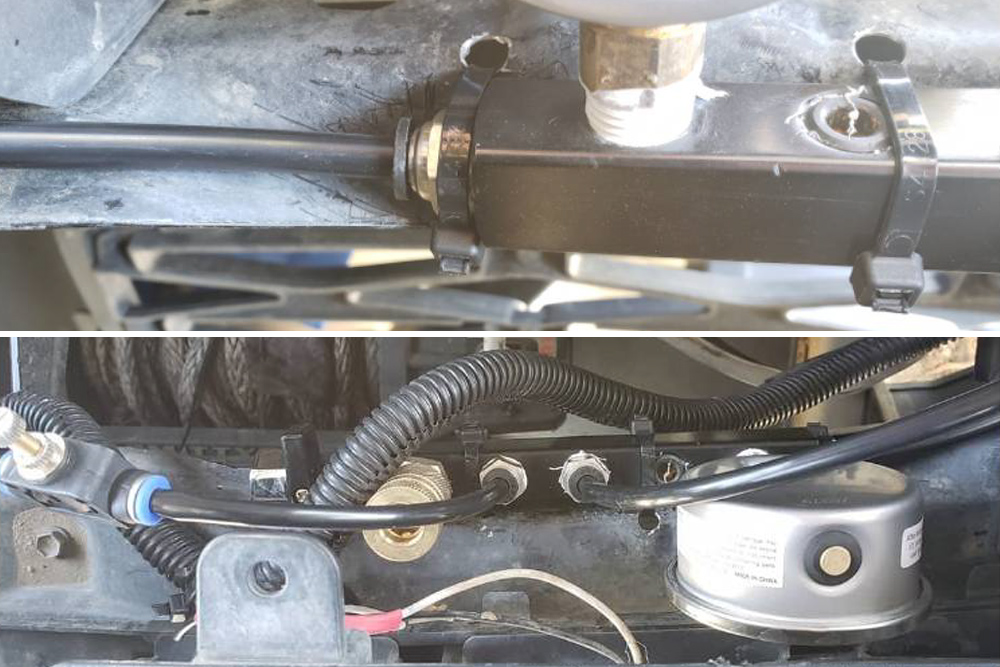

Step 5. Connect OD Male Thread to Manifold

Once everything drilled up, start connecting the OD male thread to the manifold then secure the manifold by using a zip tie.

Then, secure the front air inflation with OD quick connect nylon tube. Lastly, just connect the tube to the manifold to complete this step.

Note: The picture above there was two OD Nylon tube the one without valve control goes to the rear and the one with the control is for the front. The picture below the nylon tube is coming from the ARB air compressor to the air manifold.

Step 6. Cut Pneumatic Air Line + Connect Male Thread to Air Chucks

Cut the remaining Pneumatic Air Line 1/4″ OD Pneumatic Nylon Tube, into four pieces of 4′ in length.

Connect the 1/4″ PT male thread 6mm straight pneumatic push-in quick fitting connectors and the air chuck, Heavy Duty Closed Flow Lock On Tire Chuck (or the Haltec H-5265 Standard Bore Lock-On Air Chuck).

You going to need eight air chucks.

Step 7. Test Air System For Calibration

Test your air system, calibrate if you have to. Use a spray bottle with water and soap to see if you have an air leak.

Fast and easy modification and installation; plus, you can add air tank if you want.

Overview & Final Thoughts

Price may vary; I spent $134.00 for this project and 30 minutes of labor.

Airing down from 35 psi to 19 psi is about 5 minutes and airing up from 19 psi to 35 psi is 5minutes as well.

That is a minute, twenty-five seconds each tire, a minute, and twenty-five of not squatting down. You can use a bigger hose if you want the faster result but that is all up to you.