Like many others, my 4Runner is both my daily driver and weekend warrior. As my adventures evolved from short day trips to extended camping excursions, the need for a portable fridge became increasingly apparent – especially with my always-hungry 5-year-old son tagging along. However, I didn’t want to spend a fortune on pricey gear plates or commit to permanent modifications.

So, I started doing research and came across a super interesting product. It was a no-drill option that used the existing mounting points inside a vehicle. The issue is that it was only made for the Wrangler. I knew this would be my solution, and thus began my journey to figuring out how to make this a reality. Fortunately, I found Petersen Welding & Fabrication, to create this one-of-a-kind product for me.

Today, I’m thrilled to unveil the first-ever (to my knowledge) non-drilled fridge slide for the 5th Gen 4Runner. While this is still a prototype, it is exactly what I envisioned and is perfect for my off-road adventures.

Table Of Contents

Local Seattle Welder/Fabricator

- Email: petersenwelding2791@gmail.com

- Website: Petersen Welding & Fabrication, LLC

Kristin and Kyle own Petersen Welding & Fabrication, LLC, and are located in the greater Seattle area. Kyle does the bulk of the labor and welding, while Kristin is in charge of the business’s back end and creative vision. They have worked in the welding industry for many years and have tons of experience.

Fun fact: They both love exploring the PNW and have previously owned a 4Runner!

Why This Design Is Awesome

At the start of Summer 2023, I had just acquired my first portable fridge. At the time, I was planning tons of day trips and BBQs for my group, PNW Overlanders. It became apparent that I needed a way to secure everything so that it wouldn’t move around on the trails.

I wasn’t looking to add much more weight to the 4Runner, so a gear plate and drawers were out of the question. I also didn’t want to drill into the cargo floor.

After having no luck in my search, I started branching out into solutions for other vehicles to try and retrofit them. Then, I found Rebel Off-Road’s Jeep Gladiator JT Fridge Slide Mount. This was exactly what I was looking for; however, there was no way to modify it to fit the 4Runner. It wasn’t until my dog trainer recommended me to his family’s welding business that I could find my solution.

My goal with this slide was to secure a fridge without spending a small fortune and be easily removable. As someone who uses her 4Runner to pick up groceries, take the dogs around, and haul home renovation supplies, I frequently need my entire cargo area available.

Why A Slide Is Important

First of all, it’s a safety concern. If you were to get into an accident and the 4Runner rolled over, your unsecured fridge could go flying and hurt someone.

I also think it’s necessary to stay organized. Before the slide, I put my fridge on one side and all my gear on the other. After a day of off-roading, I would find everything scattered because nothing was secured.

Finally, it also provides easier access to your fridge. With a slide, you no longer have to half-climb into your cargo space. Plus, you avoid the added wear and tear of constantly dragging your fridge in and out.

Compatibility

The most important part of this slide was that it could fit my fridge. At the time, I had just bought a Dometic CFX3 35 and also wanted a little extra space to fit something larger in case I ever upgraded.

With this in mind, I sent the base measurements over and we were off to the races.

Note: This slide is also able to accommodate the ICECO VL45ProS as well.

Features

Here’s a quick breakdown of the slide’s design…

- Price: $287.00

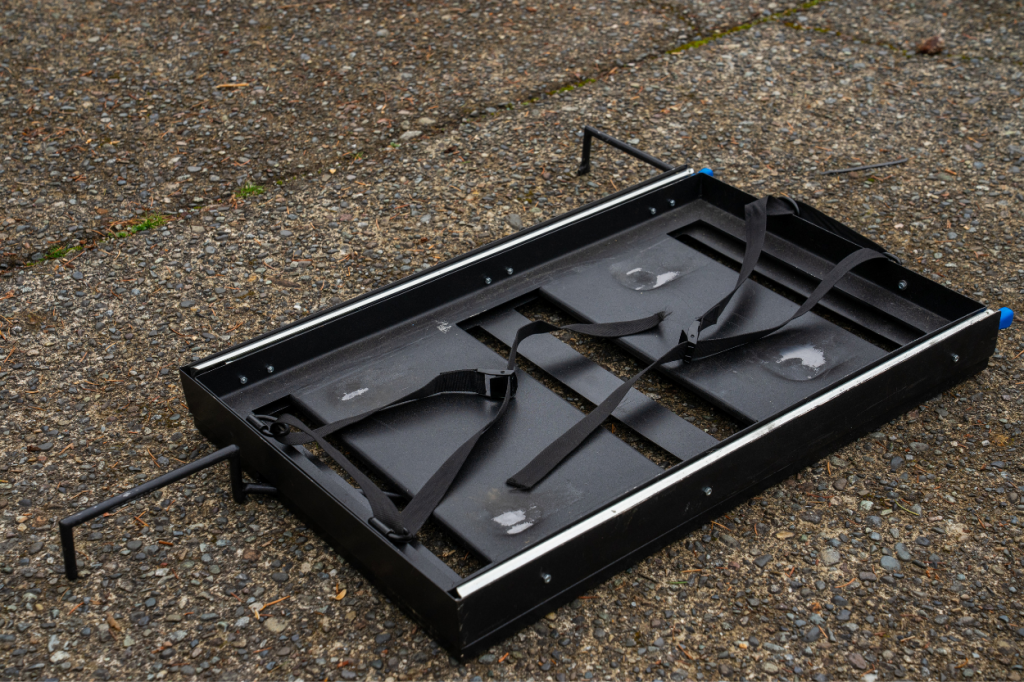

- Dimensions: 18″ (W) x 28″ (L) X 2.5″ (H), 54″ (L) – when fully extended

- Material: Thin Gauge Steel

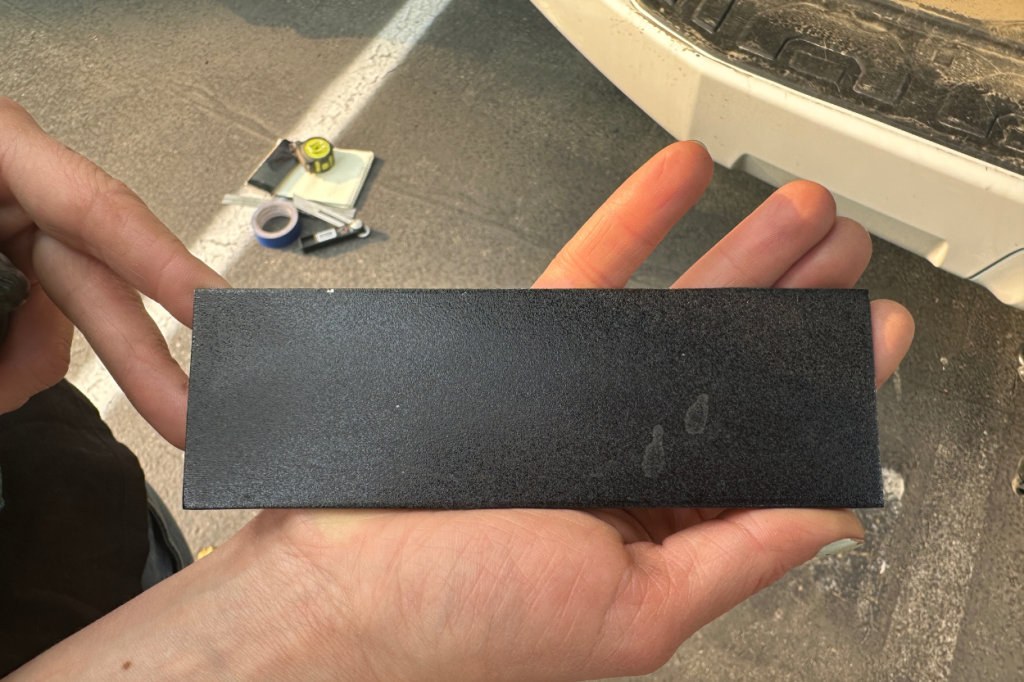

- Paint: Black Bed Liner Paint

- Total Weight: ~ 43lbs

- Portability: Features a side grab handle so you can easily move it around when needed, and the arm fits in perfectly when removed

- Compatibility: Works with the OEM Toyota All-Weather Floor Mat

The Build Process

This project took about three months to complete. Here is a quick overview of each phase.

Phase 1. Design

The first part of this process was figuring out how the fridge slide would look and be mounted. I had a few requirements: no-drill mounting, space for my dogs, and lightweight so that I could easily remove it when not needed.

Securing the slide was the toughest part of this entire build. We had to get creative because I didn’t want to make any permanent modifications to the 4Runner. We also needed to make sure it stayed in place when I pulled the fridge out.

I had originally suggested securing the slide to the mounting point below the rear window. This is where many people secure their cargo MOLLE panels. However, that may not support the fridge’s weight when on the trail. Eventually, we found that mounting it to the D-rings would make the most sense.

We also initially discussed making the slide out of aluminum to save weight. However, considering the weight and wear and tear the slide would be subject to, steel was the better choice. We opted for thin gauge steel as a weight-saving compromise.

Finally, we coated the slide with a bedliner instead of powder-coating or painting as it was the most affordable and durable of all three options.

Phase 2. Building & Test Fitting

The next step was to source the slide mechanisms and start building out the base of the fridge slide.

It took about 3 weeks to get everything finalized and welded together, but after that, it was ready for the first test fit. We tested fitment for the cargo area, my Dometic fridge, and that the drawer slides could support the weight.

After confirming everything was set, we moved on to figuring out the placement of the mounting pieces. We had a few requirements for these pieces, starting with the fact that they had to be easy to use and removable for storage. We also didn’t want them to take up too much space.

Finally, we discussed adding a handle to the side to make moving it around much easier. The handle had to be durable to ensure it wouldn’t rip off.

Phase 3. Final Adjustments & Tweaks

Once the detachable mounting pieces were made, we tested them out with the slide.

These steel arms secure underneath the slide and project outward towards the D-rings.

Then, they are paired with the hardware attached to the D-ring to ensure no movement.

The arms are extremely easy to detach. At the end of each is a ball mechanism that allows it to slide into the cutouts of the fridge slide. They are held in with one screw on the opposite side that can be removed to detach the arms when the slide isn’t needed.

Our next step was figuring out some sort of hook or loop to secure the mounting arms to the D-rings. I left this up to Kyle and Kristin.

Finally, we had to test fit the fridge, ensuring that the mounting pieces fit perfectly.

Phase 4. Secure Fridge & Slide

The last step was to get everything secured.

With the fridge slide, we opted for a U-bolt with a mounting plate. The D-ring closest to the front of the cargo area used one U-bolt and mounting plate. At the back, we used two of the same bolts due to the angle of the D-ring. Only one bolt would have been necessary if it had been leveled with the cargo mat.

I hand-tightened these bolts, and they held up quite well. However, I recommend tightening them with a wrench for more piece of mind.

The next step was securing. I used a simple cam strap for this. While it isn’t the most robust option, I intend to upgrade it once I find a better alternative. It effectively secures the fridge but over time, I anticipate some wear and tear.

Both of these securing solutions are remarkably easy to remove when necessary. If you opt for hand-tightening, removal takes less than 5 minutes. With tightly secured bolts, approximately 7-8 minutes.

Initial Impressions

I’ve been using this fridge slide for about eight months and could not be happier. That said, this is a prototype, so it has some minor flaws.

Overall, I am super impressed with the design. It has held up well through various environments ranging from bumpy roads to sandy beaches. There is a small amount of rattling, however, that is expected when you have a large object secured to a metal frame. It’s tolerable on the road but definitely more noticeable off-road.

The slide is simple to use; securely strap the fridge in and use the levers to operate the locking slides. It’s also low profile, which is great when I am not using it.

The slides can be a bit temperamental. Sometimes, they’ll get stuck when I try to retract them. A little WD40 helped a bit with this, but using higher-quality slides may help remedy the issue.

When the slides are fully extended with the fridge, the entire assembly tilts forward. I think some counterweights in the rear or a more secure attachment point would help here.

I would also prefer a slightly simpler mounting design. We are currently testing a few different options, including…

- Carabiners – If I can find one long enough to fit between the fridge slide and the cargo D-rings, it will hold enough tension to secure everything.

- Quick Link – These are extremely durable and would allow for easy installation and removal. However, we haven’t found the correct size yet. We may consider linking a few of them together.

Another issue with the current mounting method is that it’s side-specific and not entirely secure. I have the OEM rubber cargo mats to help keep it in place, but otherwise, the slide could shift on the factory carpeting.

Finally, I can see a bit of wear and tear on the slide’s surface from taking the fridge on and off. While this isn’t the biggest deal, a thicker liner could solve this problem.

Future Upgrades

The first upgrade I’d like is an integrated cutting board. In retrospect, this would have been easy to add and wouldn’t have taken up much more space. That would have paired perfectly with the fridge and elevated my camp kitchen setup. Plus, it’s one less thing you have to remember to pack.

Fold-out support legs would also be useful when the slide is fully extended. Of course, this would require more engineering and raise the cost but adds more stability when you’re in full camp mode and constantly going in and out of the fridge. However, the slide still supports a fully stocked 36L without support legs.

Final Thoughts

Overall, I am super excited to have this one-of-a-kind fridge slide. It has worked perfectly for my needs and I can take it in and out of my 4Runner whenever needed I also love that it is extremely portable and doesn’t take up much space when I store it at home.

If you are looking for a similar fridge slide, feel free to reach out with any questions or comments. I would also be happy to connect you with Kristin and Kyle, who can help bring your vision to life. I had such a great time working with them. They took the time to listen to my vision and brought it to life perfectly. As such, I plan to continue to create products with them that feature no-drill designs for everyday items.

If you have any suggestions, feel free to share them below!

Very interesting solution! Always neat to see what a fabricator comes up with. Support your local fab companies!

Love this idea. Only thing I would change is adding a turnbuckle bolt instead of the Ubolt. It would have to be a pretty small turnbuckle but you can find them everywhere.